Dented Can Inspection

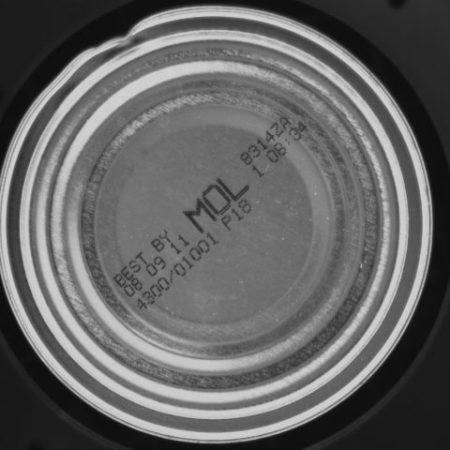

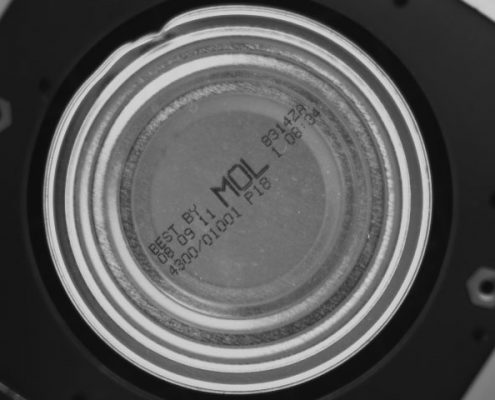

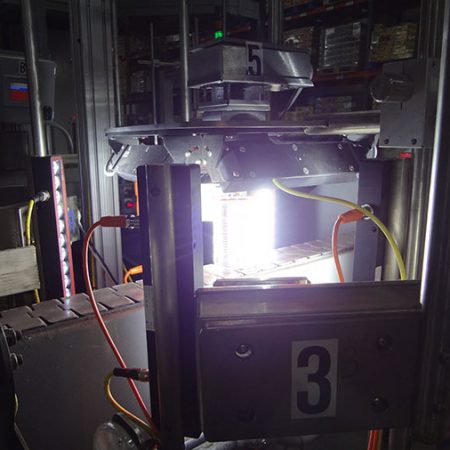

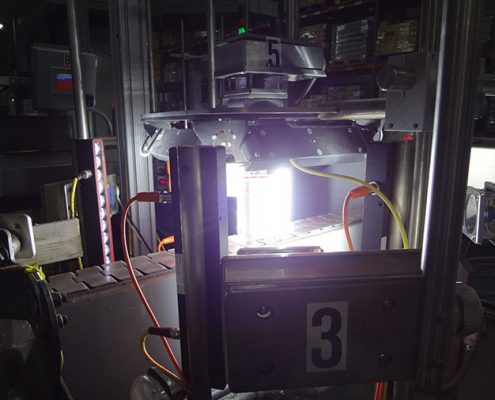

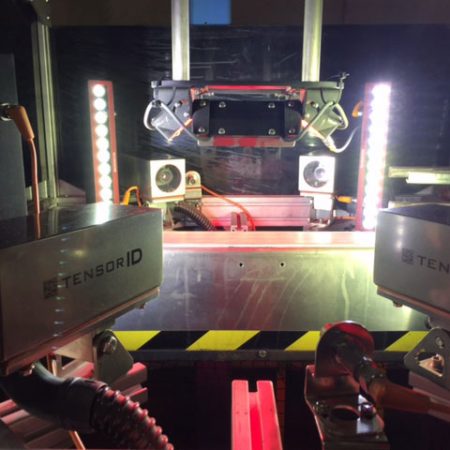

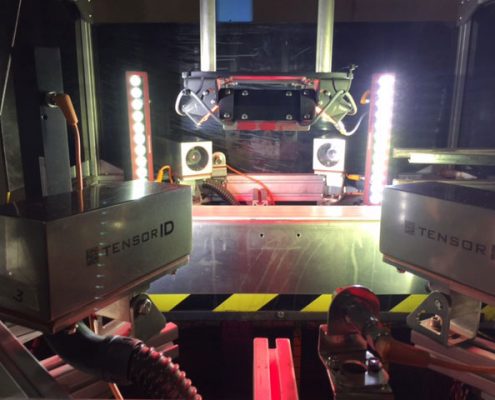

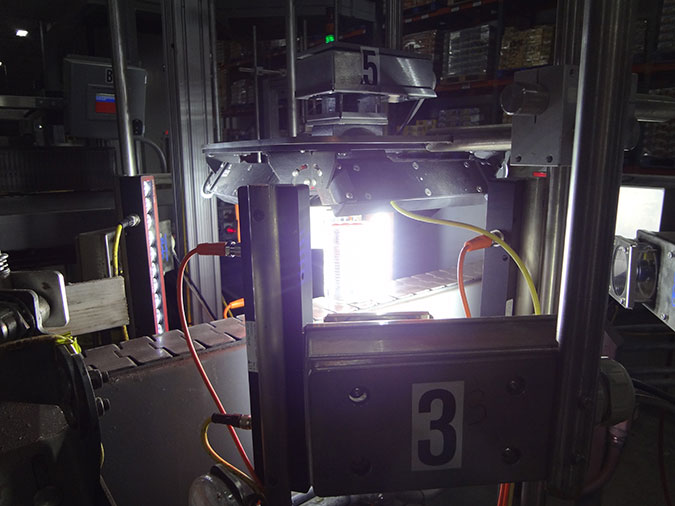

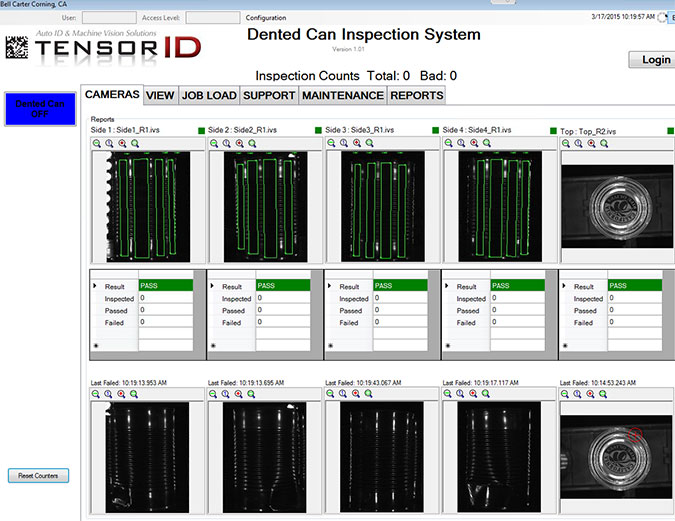

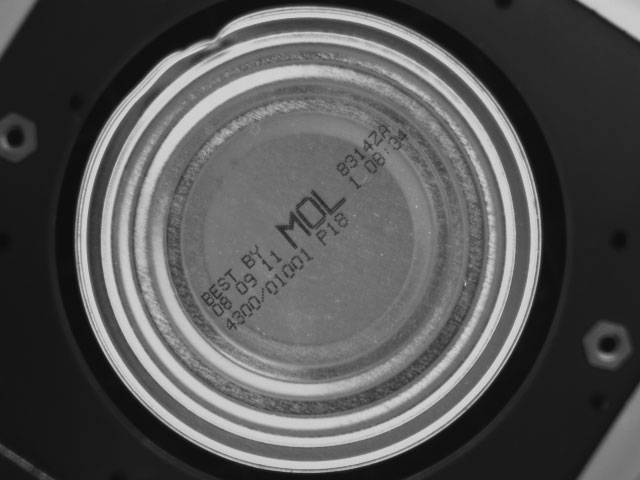

Dented Can Inspection: Tensor ID, Inc. , a leader in vision inspection systems has developed an inspection system for looking at dents on cylindrical product “Cans” specifically for today’s high-speed food and beverage industry. All body or rim dents that are detected get tracked and rejected to ensure that only quality products are produced.

By reliably detecting package defects, the TID system ensures that defective cans do not reach the retail shelf, where they can lead to costly product recalls, retailer complaints and consumer harm that can lead to liability issues. This, in turn, protects the brand image, an invaluable asset that is easy to lose but difficult to regain.

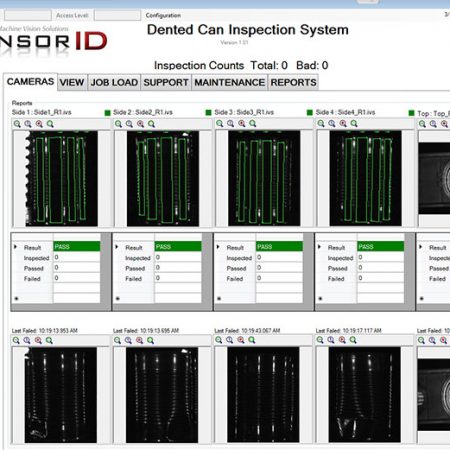

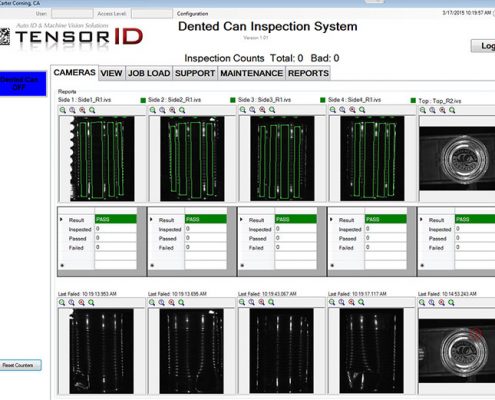

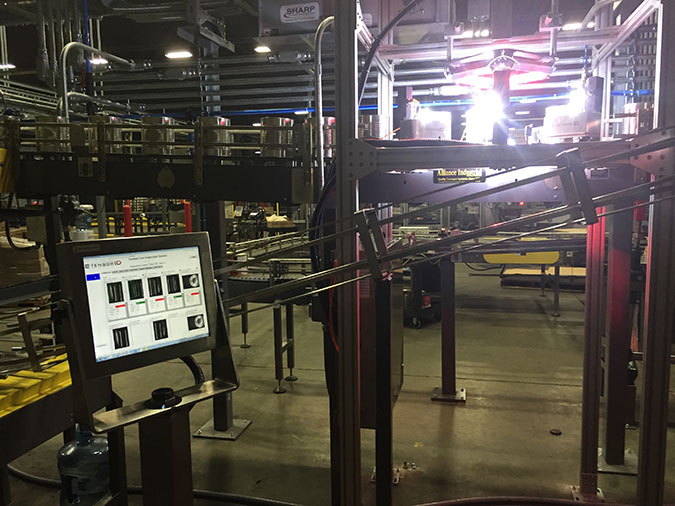

The TID system is easy to use, enabling operators to set up inspections and perform automatic changeovers using a user-friendly touch-screen menu on the system’s GUI. Tensor ID, Inc. installs the turnkey system over an existing production line, saving valuable plant floor space and installation time, and provides startup run testing and operator training as part of the implementation.

Improve your Dented Can inspections by contacting us today!